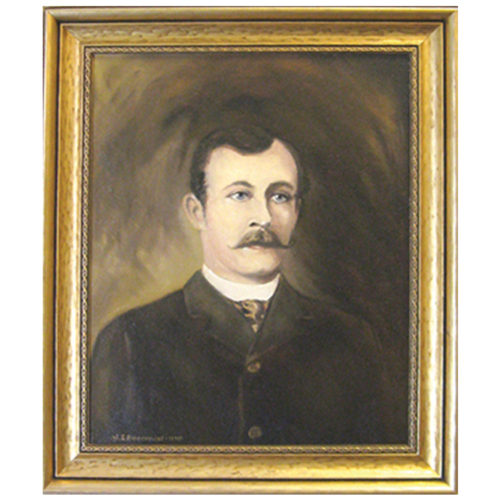

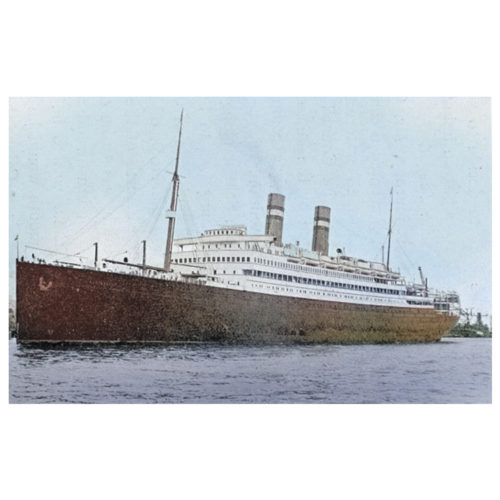

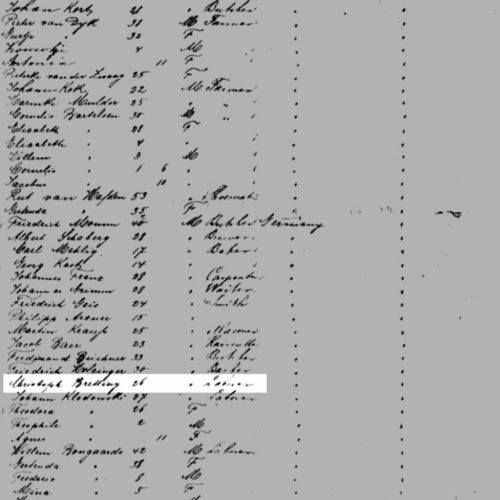

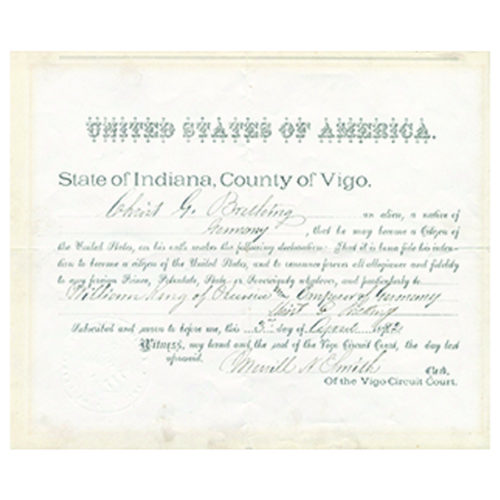

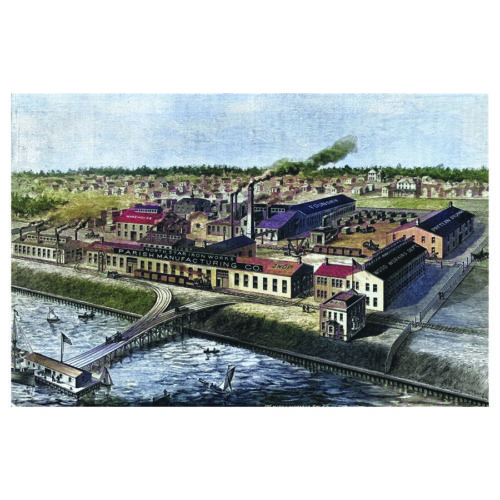

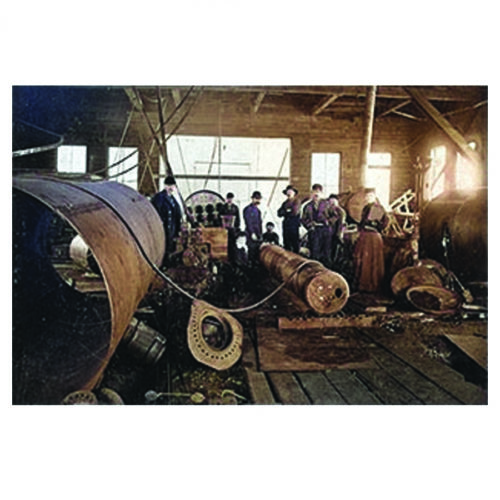

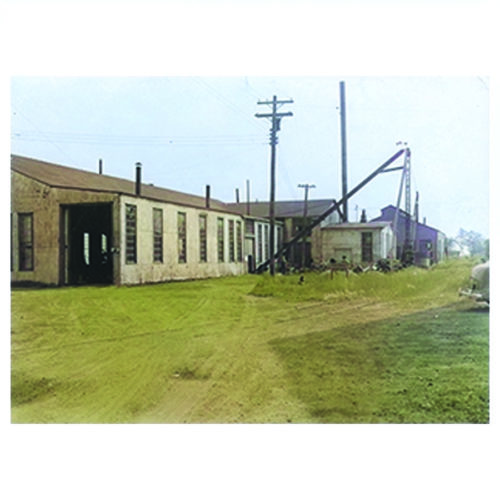

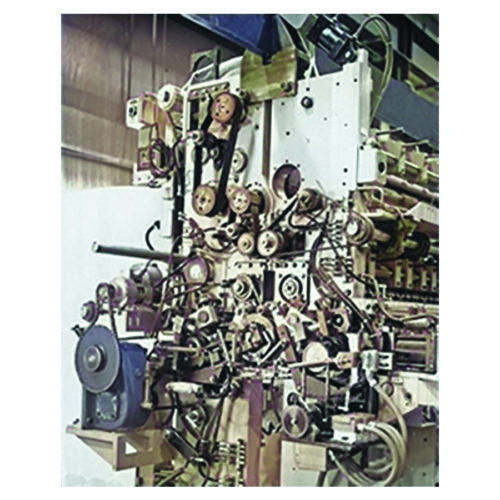

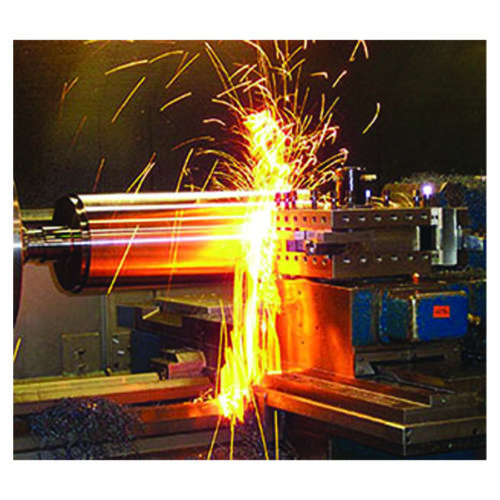

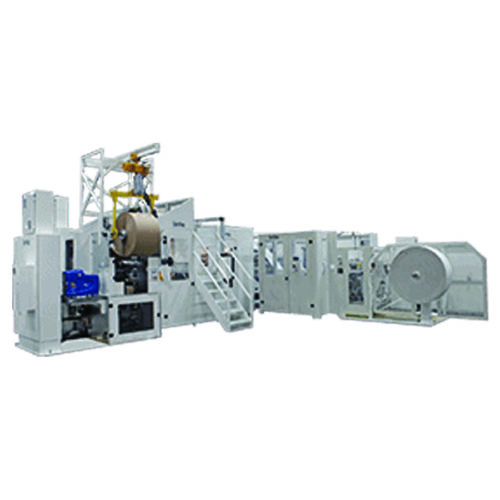

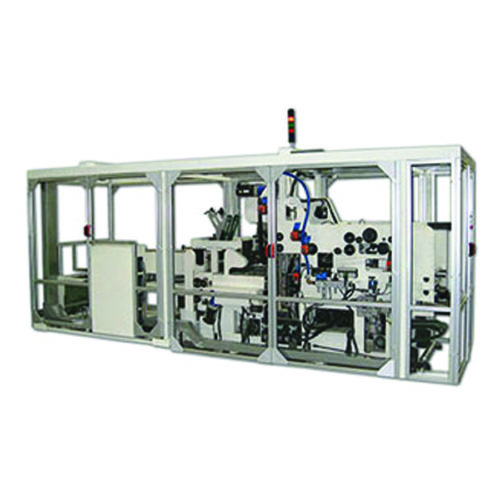

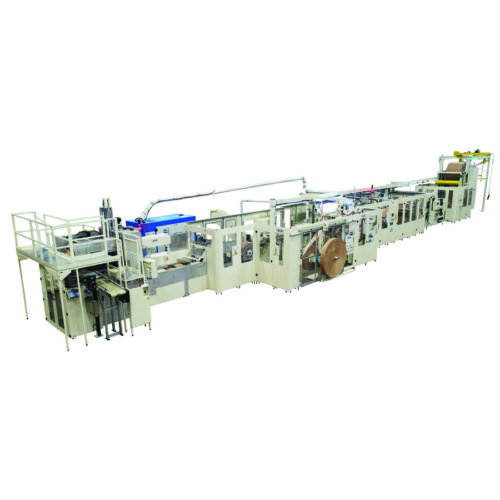

C.G. Bretting has served the converting and contract manufacturing industry for over 125 years.

We work to deliver reliable, durable and innovative converting equipment that meets our customers’ needs. Consistently, we exceed customer expectations and provide unsurpassed customer service. You can learn more about C.G. Bretting Manufacturing and its history through the following resources.